Ensure Project Success: The Relevance of Aftermarket Construction Parts Procurement

Ensure Project Success: The Relevance of Aftermarket Construction Parts Procurement

Blog Article

Increase Efficiency With Aftermarket Components: a Guide for Heavy Machinery Owners

Benefits of Aftermarket Parts

Owners of hefty equipment can take pleasure in countless benefits by deciding for aftermarket parts over original equipment maker (OEM) components. Aftermarket parts are usually a lot more affordable than OEM components, permitting machinery proprietors to minimize upkeep and repair work prices without compromising on high quality.

Another advantage of aftermarket parts is the wider choice available out there. Given that aftermarket producers focus on generating particular elements, machinery owners have accessibility to a broader variety of options to fit their demands. This selection can result in improved performance and effectiveness of the equipment. Aftermarket parts are understood for their quality and dependability, with lots of meeting or surpassing OEM requirements. aftermarket construction parts.

Lastly, selecting aftermarket components can also cause faster fixings and minimized downtime. With much easier schedule and fast shipping options, machinery owners can obtain their devices up and running once more quickly, decreasing disruptions to their operations.

Picking the Right Aftermarket Parts

When taking into consideration aftermarket components for hefty equipment, it is necessary to focus on compatibility and top quality to make certain ideal performance and longevity of the tools. Picking the appropriate aftermarket components can be a crucial choice for heavy machinery proprietors as it straight influences the performance and reliability of their devices.

Secondly, top quality must never ever be endangered when selecting aftermarket parts (aftermarket construction parts). Going with top notch parts makes certain toughness, integrity, and overall efficiency of the equipment. It is recommended to resource aftermarket components from trustworthy manufacturers or distributors recognized for their quality criteria

In addition, considering variables such as service warranties, consumer evaluations, and compatibility with existing systems can additionally help in making the appropriate option. By prioritizing compatibility and high quality when picking aftermarket parts, hefty machinery proprietors can boost the effectiveness and durability of their equipment.

Installation and Maintenance Tips

For effective procedure and long life of hefty machinery, proper installment and normal maintenance are extremely important. When installing aftermarket components, useful link guarantee that you thoroughly follow the manufacturer's guidelines to guarantee ideal performance. By prioritizing installation and maintenance procedures, you can make the most of the performance and life expectancy of your hefty machinery, inevitably saving time and money in the lengthy run.

Cost-Effectiveness of Aftermarket Parts

Correct installation and normal maintenance are fundamental facets for hefty machinery proprietors intending to assess the cost-effectiveness of aftermarket components for their devices. While original devices Read More Here manufacturer (OEM) parts are recognized for their top quality, aftermarket components use a more cost-effective solution without jeopardizing efficiency. By very carefully assessing the top quality and compatibility of aftermarket parts with their equipment, proprietors can strike a balance in between cost-effectiveness and performance, ultimately optimizing the performance and long life of their hefty tools.

Making The Most Of Performance With Aftermarket Upgrades

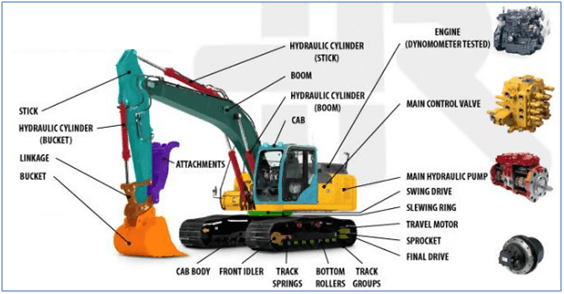

To improve operational efficiency and productivity, hefty machinery owners can efficiently take full advantage of effectiveness through calculated use of aftermarket upgrades. Aftermarket upgrades offer the opportunity to customize heavy equipment to specific functional requirements, resulting in boosted performance and output. Updating elements such as engines, transmissions, hydraulic systems, and tracks can significantly improve the general performance of the machinery.

Consistently evaluating the performance of hefty equipment and determining locations where aftermarket upgrades can be useful is vital for making best use of effectiveness. By purchasing high quality aftermarket parts and upgrades, machinery owners can attain higher degrees of efficiency, ultimately bring about cost savings and enhanced operational results.

Conclusion

In final thought, aftermarket parts offer countless benefits for heavy machinery owners, consisting of cost-effectiveness, boosted effectiveness, and modification options. By picking the best aftermarket parts, following appropriate installation and upkeep treatments, and making best use of upgrades, hefty equipment owners can enhance their equipment's performance and durability. Investing in aftermarket parts can ultimately cause boosted productivity and reduced downtime, making it a worthwhile factor to consider for owners aiming to enhance their equipment procedures.

Proprietors of hefty machinery can enjoy many advantages by choosing for aftermarket components over initial equipment manufacturer (OEM) parts. Aftermarket parts are usually extra budget friendly than OEM parts, enabling equipment owners to decrease maintenance and repair expenses without compromising on high quality. By thoroughly evaluating the top quality and compatibility of aftermarket parts with their machinery, owners can strike a balance in between cost-effectiveness and performance, eventually making the most of the effectiveness and longevity of their hefty equipment.

In verdict, aftermarket parts use countless advantages for heavy equipment proprietors, including cost-effectiveness, raised performance, and modification choices. By selecting the right aftermarket parts, complying with proper setup and upkeep procedures, and making the most of upgrades, heavy machinery owners can increase their equipment's efficiency and durability.

Report this page